electrical motor friction test|electric motor noise testing : custom When a motor isn’t working right or fails, you can use testing to track down the most probable cause of the problem. You can also use test results as a measure of a motor’s performance. That data, in turn, can inform .

Nosso software suporta jogos de cassino, aceita apostas ao .

{plog:ftitle_list}

Canada. pm. Current local time in Canada – Ontario – Toronto. Get Toronto's weather and area codes, time zone and DST. Explore Toronto's sunrise and sunset, moonrise and moonset.

Electric motor testing is the process of evaluating the performance, reliability, and safety of an electric motor before manufacturing begins. It includes testing factors like . Achieving exact synchronous speed in an induction motor is impossible, so it is assumed by considering the slip as zero, creating infinite impedance in the rotor branch. This test provides information about no-load . But by dedicating time to thorough motor testing — both in regular, routine maintenance programs and at the first sign of trouble — motor issues can be reliably predicted, prevented, isolated, and resolved with .

Troubleshooting Motor Vibration: Step-by-Step Guide. Follow these steps to troubleshoot motor vibration: Collect vibration data during the dynamometer test using appropriate sensors. Analyze the vibration data for .This is a complete list of Motor Tests as Listed under the IEEE std, with associated experience from 3Phi Reliability. Bearing Temperature Simple trending, Better Methods for on condition Lubrication. 3Phi Reliability . When a motor isn’t working right or fails, you can use testing to track down the most probable cause of the problem. You can also use test results as a measure of a motor’s performance. That data, in turn, can inform .Specialized measuring instruments are necessary in order to test electric motors, for example in design, development, and production processes. This article introduces principal methods for testing electric motors and explains .

Related Posts: Losses in a Motor – Power Stages in an Induction Motor Block Rotor Test of Induction Motor. The block rotor test is performed to determine the short circuit current I sc power factor at short circuit cos ф sc, total equivalent . Key learnings: No Load Test of Induction Motor Definition: A no load test of induction motor is defined as a test conducted when the rotor rotates at synchronous speed without any load torque.; Purpose of No Load . In this article, we have listed a number of different tests that will check/test the motor mechanically and electronically. Tests should always be carried out by an electrically and mechanically competent person. . Locate a .During a test, an inclined plane is increased at a rate of 1.5 ± 0.5º per second by an electric motor until the test block begins to slide. The initial movement of the sled is the Slide Angle or Coefficient of Static Friction of the material. When the test block just begins to slide a photo-optical sensor automatically stops the inclined

are some differences in the EV driveline that friction and wear testing can address. These include the fact that lubricants for EVs must be adapted to high-speed reduction gears and also need to withstand high speeds of electric motors, which can reach up to 20,000 rpm [2]. To execute tribological testing, there are many different tests that Checking Spring Pressure for Proper Contact. Proper spring pressure is vital for maintaining optimal contact between the brushes and the commutator or slip ring. Inadequate spring pressure can result in poor performance, increased wear, and reduced efficiency of the electric motor. It is essential to periodically check and adjust the spring pressure to ensure .

A conventional electric motor works because a rotating magnetic field, set up in a fixed structure called a stator, engages with the magnetic field of another structure called a rotor, causing . Prepare for your electrical motors exam or enhance your knowledge with our collection of 50 multiple-choice questions and answers. Test your understanding and expand your expertise in electrical motors with this comprehensive resource. The aim of the article is to present a new idea of limiting the bearing voltage in electric machines with permanent magnets through the use of a shielding winding placed in stator slot wedges.

There are two types of losses occur in three phase induction motor.These losses are, Constant or fixed losses, Variable losses. Constant or Fixed Losses. Constant losses are those losses which are considered to remain constant over normal working range of induction motor.The fixed losses can be easily obtained by performing no-load test on the three phase . Electric motors (EM) replace the ICE . specific questions are dealt with. Generally, mechanical losses comprise windage (due to air drag between stator and motor), friction (due to load couplings), bearing (due to wear and tear of ball bearings), and stray losses (due to sudden load transients and mainly depend on the speed), mainly depending .Electrical testing and diagnostics can be segmented to two main categories: Static (De-Energised) Electrical Testing – When the supply to the machine is isolated, electrical tests are carried out to find faults or to provide data which can be used as a benchmark or trended over time. Dynamic (Energised) Electrical Testing –

Basic Maintenance and Testing of DC Electric Motors . Part 2 . Howard W Penrose, Ph.D., CMRP . President, SUCCESS by DESIGN . Introduction . In Part 1, we discussed the basic makeup and operation of DC electric motors. In this article, we . Figure 1: Coefficient of Friction . 0 0.05 0.1 0.15 0.2 0.25 0.3 0.35

The heat generation depends on the stator windings current, electric power, and dimension of the motor. Therefore, motor efficiency plays a crucial role in realizing the rated thermal performance. The test conducted by .A chassis dynamometer.. A dynamometer or "dyno" for short, is a device for simultaneously measuring the torque and rotational speed of an engine, motor or other rotating prime mover so that its instantaneous power may be calculated, .

Friction Analyzer Motion Analyzer Stepper Motors Electric Motor Testing Equipment. M.E.A. Testing Systems develops and supplies state-of-the-art electric motor test equipment to many of the leading manufacturers and users throughout the world. M.E.A. testing systems can be found in a wide range of locations, including R&D laboratories .

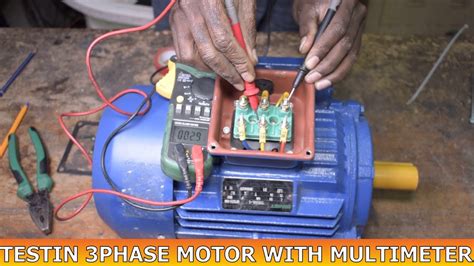

• Reduce friction and prevent wear • Protect bearings against corrosion • Act as a seal to prevent entry of contaminants . no more than 1 to 1.5 NLGI grades in this test. An electric motor bearing grease that softens more than that may leak out of the bearing with age. Grease Compatibility With some exceptions, greases with different . Excessive friction, misaligned parts, or worn-out components can affect the motor’s performance. Lubricate or replace any damaged or worn parts as necessary. 5. . Testing an electric motor with a multimeter is a valuable skill that can save you time, money, and frustration. By following the step-by-step process outlined in this guide, you . This paper provides a new approach for emulating electric vehicle (EV) braking performance on a motor/dynamometer test bench. The brake force distribution between regenerative braking and friction .

compression test lab

Friction drives allow you to use a super cool rc motor to drive your bike. Friction drives are rare. Hub motors are everywhere, the basis for 95% of modern ebikes. Some people like the motor noise a friction drive makes..more of a sensation of riding an electric bike. Depending how configured, a friction drive can be more efficient than a hub . This principle, when applied to both AC and DC motors, is the reason why the motor shaft rotates. Figure 1 – DC injection braking of a motor In an AC induction motor, when the AC voltage is removed, the motor will coast to a standstill over a period of time, since there is no induced field to keep it rotating. The installation of the friction roller and electric motor requires proper alignment and secure mounting, with the motor wired to the battery, controller, and throttle. . Inspect the wiring: Look for any loose or damaged wires that may be causing electrical issues. Test the motor: Listen for any unusual noises or vibrations when the motor is .

smooth out the transition between friction brakes and electric motors, a first order filter with 5 Hz cut-off corrects the blending factor to be sent to the controller . 4.3. In this comprehensive guide, we compare hub, mid-drive, and friction drive systems for electric bike motors. Explore their performance, efficiency, and suitability for different riding styles. Whether you're a seasoned cyclist or new to e-bikes, make an informed decision and find the perfect motor for your electric bicycle journey. How to test an electric motor for efficiency: Measure and track efficiency: By understanding the efficiency of your electric motor, you can identify any areas where energy is being wasted. . Each type offers unique advantages and is suitable for different testing scenarios. Friction-based dynamometers provide precise measurements, while water .The aim of the paper is determining of suitable way of DC motor friction modeling. At first the basic static friction models are introduced and linear mathematical model of DC motor is established. . Modelling of the armature slotting effect in the magnetic field distribution of a linear permanent magnet motors, Electrical Eng, Vol. 84, pp .

how to test electric motor voltage

how to test an electric motor

R$ 50,00 Unidade. COMPRESSOR SABROE 106L Juiz de F.

electrical motor friction test|electric motor noise testing